Jet Marker

Overview

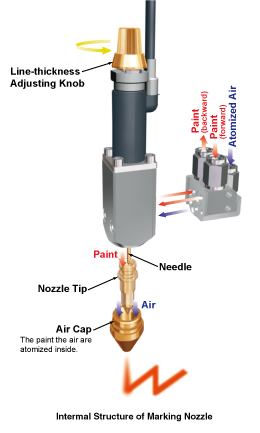

Marking is performed in such a way that the nozzle is moved along the character shape in the X-Y stage and paint is ejected each time the nozzle is opened and closed as it moves a specified distance. Shortening the ejection timing produces continuous line characters; lengthening it produces dot characters.

Feature

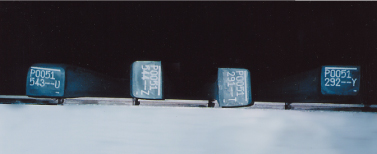

- Because one nozzle is moved in the X and Y direction to from characters, it is possible to paint any size or pattem of character or mark.

- Character shapes can be set or changed using a graphical display; when an automatic reading system is used to read characters; certain characteristics can be assigned to characters of similar shape.

- Marking of small characters can be performed.(20mm(H)×15mm(W))

- Since an atomizing nozzle is used, paint consumption is reduced, even in hot material applications.

- The amount of paint ejected is controlled for the object according to the temperature information and characters having a certain thickness can be marked. Clog-free nozzle.

Specifications

| Standard stage | A type: X-axis 600 mm x Y-axis 150 mm B type: X-axis 500 mm x Y-axis 150 mm C type: X-axis 400 mm x Y-axis 150 mm D type: 300 mm x Y-axis 150 mm |

|---|---|

| Letter size | Any desired (character height: 20mm < ) |

| Marking speed | 0.7sec/character (H=30mm, P=30mm) |

| Character thickness | 3 to 10 mm |

| Distance between characters | 30mm±5mm |

| Material temperature | Normal temperature to 1100℃ |

| Paint | ink or water-based paint |

| Tank capacity | 15 L (standard) cold-rolling steel 50 L Hot-rolling steel |

| Data setting method | Manual setting and auto linkage setting |

| Power supply | A200/220V or 400/440 V AC 50/60 Hz |

| Air source | 400 400 kPa (4kgf/cm2) or more |

| Cleaning water | 100~200kPa(1~2kgf/..) |

Contact Us

Please use this form to submit your inquiries, feedback and/or requests to NIRECO.

Tokyo +81-42-660-7358

Osaka +81-6-6190-5550