-

Print Quality Inspection Systems

-

Gluing Control Systems

- Applicator nozzles for Cold glue system

- Glue inspection system for envelopes

- The system for business forms

- Glue Monitor GM800

- Tank -Cold gluing system-

- Cold glue system

- Glue monitor system GM6600/A

- Skipmaster controller SM9000 series

- Encoder

- Electro-Pneumatic Converter

- Glue sensor

- Paper Checker PC300G / PC110A

- Responser

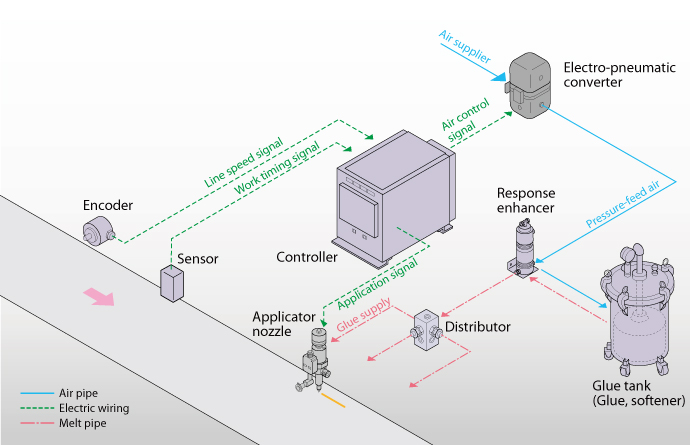

Cold glue system

Overview

Cold gluing systems are used for gluing various kinds of business forms and are excellent for bookbinding, carton gluing sealing and other applications.

Our specialized controllers respond to changes in the speed of the conveyor line and the position of the job, to automatically govern the amount of glue, the application position and length, ensuring accurate, consistent gluing and improved productivity.

System components

| System | Nozzle | Controller | Tank | Related equipment |

|---|---|---|---|---|

| Business form gluing systems | AN10-A03 AN10-A24 | SM9000 LM200 | GR-20BF GR-10HA GR-5HN | PC110 RS10 |

| Web offset printing Bookbinding Bag making Atomizing | AN20-CG-E03-N06 AN10-ABF-N AN10-A03 AN10-AA03 AN10-AAW-N | SM5000 SM23 (Select by functions) | GR-20BF(0.2MPa) | Responser RS10 |

| Carton Cardboard | AN20-CH-E03-N04 AN10-E12LS AN10-E12MN AN10-E24CD | SM5000 SM23 (Select by functions) | GR-20HN GR-10HA GR-5HN (Select by volume) | Paper checker PC300G |

Overview of system components

SM9000 series Controller

The touch-screen panel displays all the settings, making the system easy to program―even for a beginner.

▸SM9000 Details

Applicator nozzles

Glue can be applied rapidly and consistently, intermittently or continuously, driven electronically or pneumatically, to a high degree of precision.

Tank

The glue in the tank is propelled by compressed air from a pneumatic source to the applicator nozzle. The tanks have a glue volume warning device.

▸Tank Details

Encoder

The encoder measures the timing of the gluing and the speed of the conveyor line, and sends signals to the controller.

▸Encoder Details

Distributor

Glue is supplied from the glue pressure-feed tank to the nozzles.

Responser

This device can greatly improve the glue pressure response when the gluing equipment is rapidly starting and stopping.

▸Responser Details

Electro-pneumatic converter EN40

The EN40 converts electrical input signals into air pressure signals. Regardless of the line speed, the EN40 makes adjustments to ensure a consistent glue application.

▸EN40 Details

Paper Checker PC300G

This is a double-sheet feed detector for box-making machines. Besides paper, it can also be used with aluminum laminated paper, poly-laminated paper, plastics and a range of other materials. It can also handle a wide range of thickness, and the thickness in use can be selected from a switch on the operation panel for changeovers. The PC300G can detect double sheets that may occur due to the material or to operator error, and immediately prevents them from being fed in.

▸PC300G Details

Contact Us

Please use this form to submit your inquiries, feedback and/or requests to NIRECO.