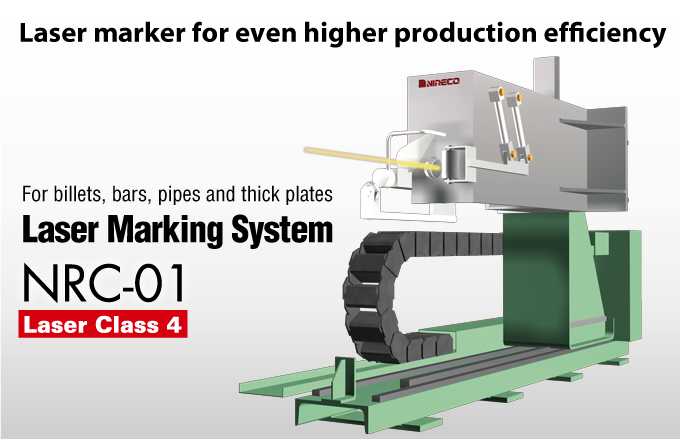

Laser Marker

Overview

Nireco’s laser marking system can mark directly onto the sides or ends of thick plates moving on the production line. It can write text information necessary for quality control and inventory management, and barcodes that are essential for logistics management, yielding major cost reductions.

Using our abundant experience and expertise in the steel industry, this marking system marks quickly and accurately, on hot metal or on cold metal. It is also highly environmentally stable, for dependable long-term use.

Feature

- Handles all surface states.

- Writes on all casting surface irregularities.

- Harmless, water-soluble ink.

- Newly-developed surface coat application nozzle eliminates ink blockages.

- Low laser marker running cost – just surface coat and electricity.

- High printing speed allows instant marking.

- Prints regular, 2D, RSS and other types of barcode.

- Prints on hot materials at up to 900°C, as standard.

Printing sample

Specifications

Material specifications

| Thickness | 4.5mm – |

|---|---|

| Temperature | Room temperature to 600℃ |

| Warping | ±50mm |

| Curved surface | 3R |

Printing specifications

| Character size | 3.5mm – |

|---|---|

| Color | Primer color (e.g., white) |

| Printing speed | 50 characters per 3.5 sec. |

| Focal depth | ±2mm |

| Basic marking range (when head is fixed) | 105mm×105mm |

| Printing speed when moving | 200mm / sec |

Market specifications

| Laser specifications | Co2 30w |

|---|---|

| Primer nozzle (Nireco Corporation) | GJ0381.0-00 |

| Primer coat (Nireco Corporation) | NRC-850, NRC-1100 |

| Plate temperature measurement | By data input or actual measurement |

| Marker head movement mechanism | Head positioned by dual- or triple-axis servo motor |

| Protective structure | Dual-layer air-cooled case |

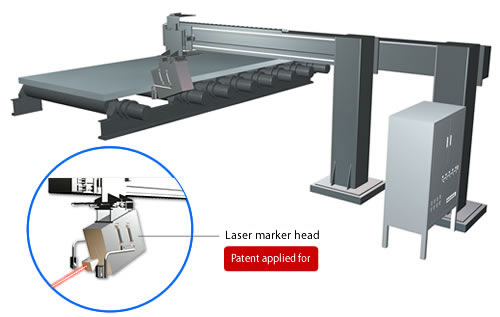

Image of the laser marker at work

Contact Us

Please use this form to submit your inquiries, feedback and/or requests to NIRECO.

Tokyo +81-42-660-7358

Osaka +81-6-6190-5550