Electrode Sheet Inspection System Mujiken-RB

Overview

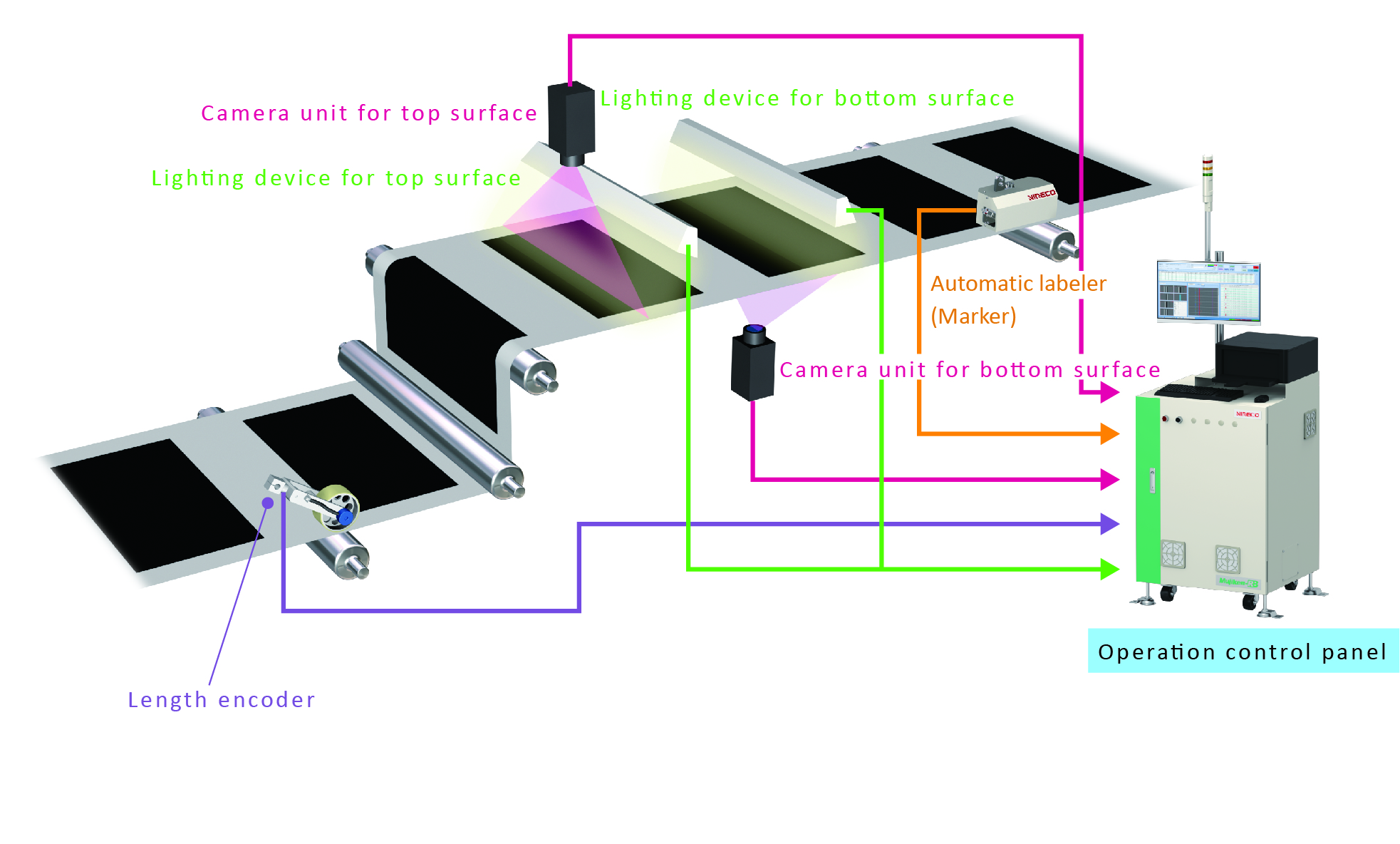

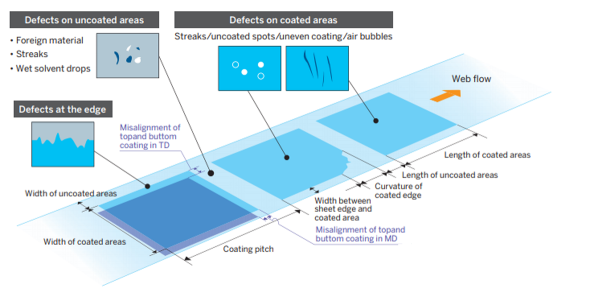

Equipment that inspect continuously and quickly moving electrode sheet surfaces is called “Electrode sheet Surface inspection systems”. The monochrome line sensor camera is used to capture the illuminated material surface with LEDs, and image processing analysis is used to detect and judge defects and measuring coating pattern at the same time. The detected defects and dimensions can be sorted and categorized, and the defect data and images can be saved.

Benefits

-Improved quality

-Improved production efficiency

-Reduced labor costs with automation

-Cause analysis from data

Applications

-Battery materials

-Electrode sheet

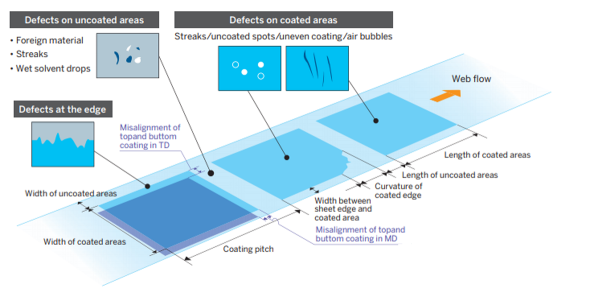

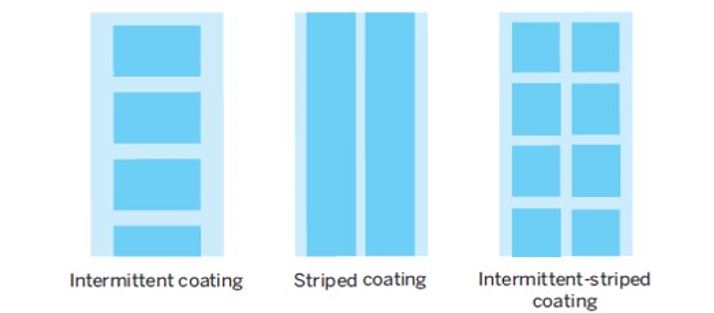

Examples of Inspection and Measurement

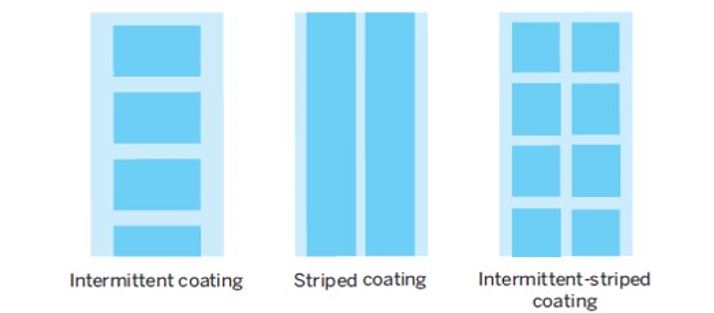

Applivcatable electrode patterns

*Please consult us for other examples of defects and pattern measurement functions not listed above.

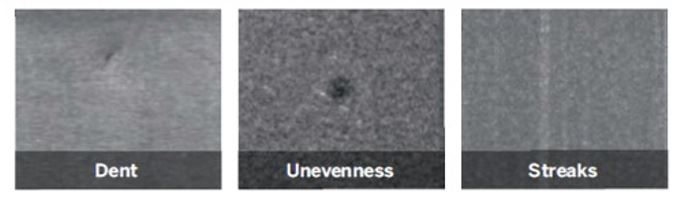

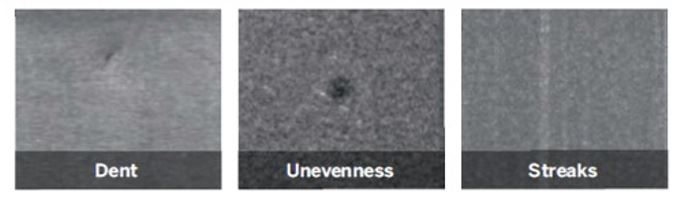

Defect detection examples

*In addition to the ones shown avobe, the system can also detect defects such as fish eyes, agglomerates, and wrinkle.

Options

-Labeler, pen marker, inkjet printer

-Viewer software (viewing, re-inspection)

-Remote maintenance

-Various customization(upper-level communication, MES communication, slit support)

Contact Us

Please use this form to submit your inquiries, feedback and/or requests to NIRECO.

Tokyo +81-42-660-7330

Osaka +81-6-6190-5552

Benefits

-Improved quality-Improved production efficiency

-Reduced labor costs with automation

-Cause analysis from data

Applications

-Battery materials-Electrode sheet

Examples of Inspection and Measurement

Applivcatable electrode patterns

Defect detection examples

Options

-Labeler, pen marker, inkjet printer-Viewer software (viewing, re-inspection)

-Remote maintenance

-Various customization(upper-level communication, MES communication, slit support)

Contact Us

Please use this form to submit your inquiries, feedback and/or requests to NIRECO.

Tokyo +81-42-660-7330

Osaka +81-6-6190-5552