Mujiken Express

Overview

Equipment that inspect continuously and quickly moving plain surfaces material, such as high-performance film, Optical films, paper and metal is called “Surface inspection systems”.

The monochrome line sensor camera is used to capture the illuminated material surface with LEDs, and image processing analysis is used to detect and judge defects.

The detected defects can be sorted and categorized, and the defect data and images can be saved.

Feature

Even faster image processing

- High-speed, high-capacity image processing engine (twice as fast as our previous model)

- Newly equipped with a GPU! High speed inspection, various image processing

- High speed inspection (640MHz) with CoaXPress (Japan Industrial Imaging Association standard) camera

- Long distance and high speed communication without relay board (Max. 680MHz, 50m)

Benefits

-Improved quality

-Improved production efficiency

-Reduced labor costs with automation

-Cause analysis from data

Applications

-Functional films, optical films, industrial films, general-purpose films

-Battery materials

-Electronic materials

-Paper

-Metals (Steel, SUS, Copper, Al…)Copper, Al…)

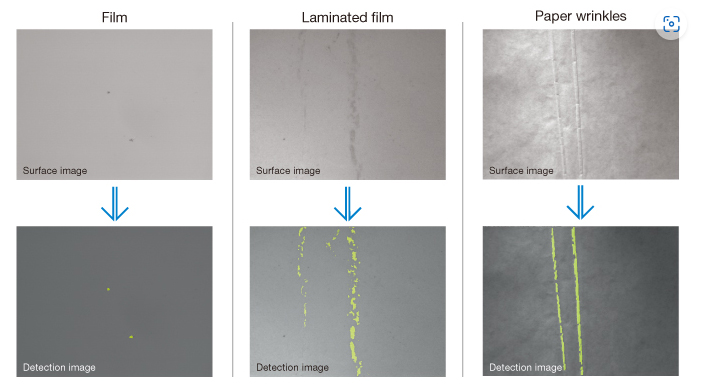

Defects

-Pinholes, fish eyes, contaminants, scratches, bubbles, stains

-Offline inspection systems ( XY Stage, Rewinder)

Please use this form to submit your inquiries, feedback and/or requests to NIRECO.

-Coating line, wrinkle, roll line

-Uneven coating, light stains

Options

-Labeler, pen marker, inkjet printer

-Viewer software (viewing, re-inspection)

-Remote maintenance

-Various customization (upper-level communication, MES communication, slit support)

Contact Us