-

Edge Position Control Systems

- High Functionality EPC/CPC Amplifier SGA3100

- Inductive Autowide Sensors AWI Series

- PHOTOHEAD PH50, PH51

- Linear Sensor LSF4096

- Analog Position Transmitter FW80

- Modular Strip Guide system controller MGC1000

- Electromagnetic CPC Sensor Model:EMW

- Capacitance Autowide AWC Series

- Electromagnetic Guidance NS-CPC Sensor

- AUTOWIDE™AWL

- Strip Guide Amplifier SGA3000

- PILOTJET

- Power Guide PG300, 500, 800

- Analog Position Transmitter FW22, FW31

- High-precision Position Transmitter GYKM-LT

-

Measuring Systems

-

Actuators

-

Movie

POWERPACK AJ02 / AJ03

Overview

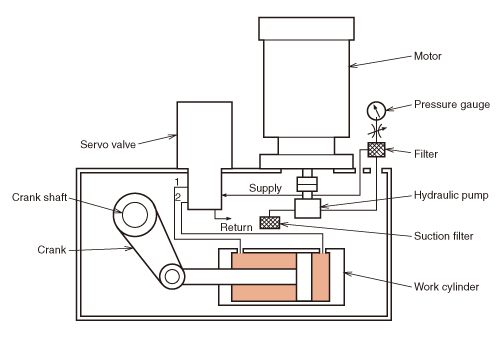

The Powerpack is a kind of an electro-hydraulic actuator. It is of the proportional positioning type and has a hydraulic work piston that is proportional to the electrical system, with the function of converting a DC electrical signal (DC 4-20mA) into a motion of the hydraulic work piston. The Powerpack is of a structure that unitizes the currenthydraulic pressure converter unit, the hydraulic pump and the work cylinder, and it does not require external piping.

Feature

- Receives electrical signals and outputs high-speed, high-powered hydraulic output.

- Because a hydraulic servo valve is used in the controller, high response and easy maintenance assure high reliability. An electric feedback system is used.

- A power supply is required only for the motor. No power supply is needed for the amplifier because it has a built-in transformer.

- Manual local operation can be selected.

- Opening output signals (4 to 20 mA) are available as standard.

- No oil leaks from joints because the work cylinder and control elements are integrated into the oil reservoir.

- No external piping is needed.

- Safety functions are provided.

The crank arm moves in the safety direction when input signals are abnormal (excessively low or high) or the wiring of the feedback potentiometer is broken. The direction for safe movement can be changed as required.

Configuration

The hydraulic unit of the Powerpack consists of an electrical current-hydraulic converter (servo valve), hydraulic pump, and actuator cylinder. The compact cast-iron reservoir incorporates an actuator cylinder, pump, crank, and feedback mechanism, and requires no external piping. An amplifier and an AUTO/MANUAL switch are provided inside the box on the reservoir to simplify operation at the workplace.

Specifications

Common Specifications

| Input signal | 4 – 20mA DC |

|---|---|

| Input resistance | 250Ω |

| Opening output signal | 4 – 20mA DC (max. load 250Ω) |

| Control action | Proportional action |

| Operating direction | Can be changed to any direction |

| Linearity | 2% |

| Hysteresis error (no load) | 2% |

| Temperature drift | 5% (0 – 60˚C) |

| Maximum crank rotation | 60˚ |

| Installation | Horizontal |

| Ambient temperature | -10 – +50˚C |

| Temperature range of hydraulic fluid | +10 – +50˚C |

| Paint | Silver |

| Manual operation function | AUTO/MAN,OPEN/CLOSE |

Specifications by model

| Model | AJ02 | AJ03 |

|---|---|---|

| Operating torque(kN·m) | Max:1.2 * Min:0.9 * |

Max:2.4 Min:1.8 |

| Maximum no-load speed (standard setting) (°/sec) | 4 – 5 | 3 – 4 |

| Hydraulic pressure (MPa) | 2 | 2.2 |

| Cylinder bore X stroke (mm) | Ø80 × 120 | Ø100 × 140 |

| Length of crank arm (mm) | 250 | 300 |

| Motor (3Ø, 4P) | 0.4kW 3Ø 4P | 0.75kW 3Ø 4P |

| Oil required (ℓ) | 18(21 for ACC) | 28.5(35 for ACC) |

| Mass (excl. hydraulic fluid) (kg) | 115 | 150 |

Contact Us

Please use this form to submit your inquiries, feedback and/or requests to NIRECO.