-

Edge Position Control Systems

- High Functionality EPC/CPC Amplifier SGA3100

- Inductive Autowide Sensors AWI Series

- PHOTOHEAD PH50, PH51

- Linear Sensor LSF4096

- Analog Position Transmitter FW80

- Modular Strip Guide system controller MGC1000

- Electromagnetic CPC Sensor Model:EMW

- Capacitance Autowide AWC Series

- Electromagnetic Guidance NS-CPC Sensor

- AUTOWIDE™AWL

- Strip Guide Amplifier SGA3000

- PILOTJET

- Power Guide PG300, 500, 800

- Analog Position Transmitter FW22, FW31

- High-precision Position Transmitter GYKM-LT

-

Measuring Systems

-

Actuators

-

Movie

AUTOWIDE™AWL

Overview

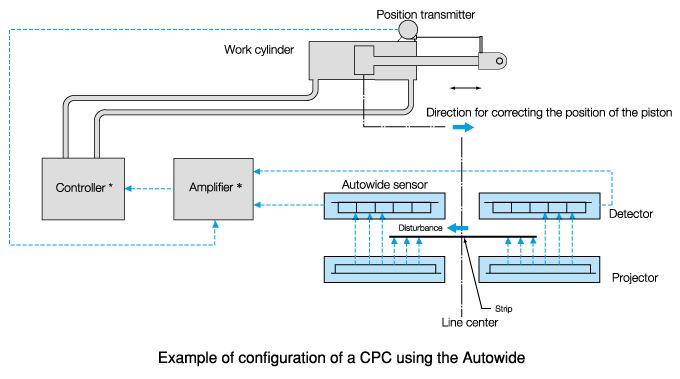

The Autowide Sensor AWL is used mainly for CPC (center position control) to detect the center line on a strip (web).

It can continuously control the center line at a constant position without changing the position of the sensor each time the width of the strip changes (large changes such as seams etc.). The AWL is a new generation of detector which uses a highfrequency LED as the projector and SPDs(silicon photo diodes) as the detector.

Feature

- The LED of the light source ensures a longer service life.

- The SPD of the detecting element ensures a higher response than conventional sensors.

- The light source is lit at a high frequency and is synchronized.There is almost no effect from peripheral light(less than 1/50,compared with a fluorescent lamp-type Autowide Sensor).

- The sensor gap be fixed at any position.

Principle of Operation

The right and left detectors detect the deviation of the strip edges from the center line, and send signals the amplifier. The amplifier amplifies the difference between the right and left signals and sends the signal to the hydraulic controller or electric controller to perform CPC. When a strip travels with its center coincident to the center of the line, the signal from the amplifier is zero. In this state, the work cylinder is positioned at the center. When a strip deviates either to the right or to the left, the positive or negative signal, which is determined by the direction for correction, is transmitted to the controller, and the cylinder works in the direction to correct the displacement of the strip.

Specifications

| Model | AWL631 | AWL781 | AWL931 | AWL1081 |

|---|---|---|---|---|

| Effective detecting length (mm) | 450 | 600 | 750 | 900 |

| Strip width (mm) | 265 (305) or more | 315 (355) or more | ||

| Power consumption (VA) | 28×2=56 | 30×2=60 | 32×2=64 | 34×2=68 |

| Mass (1set) (kg) | (5.2+5.8)×2=22 | (6.8+7.2)×2=28 | (9.1+9.5)×2=37 | (9.1+9.5)×2=37 |

| Air consumption*㎥/min | 2 | 3 | 4 | 4 |

| Sensor gap (mm) | Type T: 300~1200mm ; Type M : 1200 – 3000mm | |||

| Detecting element | SPD(silicon photo diode) | |||

| Light source | LED(Light emitting diode) | |||

| Frequency response | 15Hz | |||

| Resolution | 0.2mm | |||

| Linearity | ±1.5% | |||

| Effect of peripheral light | Almost none | |||

| Power supply | 100/110 V AC ±10% 50/60Hz | |||

| Ambient temperature | 0 – +50℃ | |||

| Painted color | Black | |||

Contact Us

Please use this form to submit your inquiries, feedback and/or requests to NIRECO.