-

Edge Position Control Systems

- High Functionality EPC/CPC Amplifier SGA3100

- Inductive Autowide Sensors AWI Series

- PHOTOHEAD PH50, PH51

- Linear Sensor LSF4096

- Analog Position Transmitter FW80

- Modular Strip Guide system controller MGC1000

- Electromagnetic CPC Sensor Model:EMW

- Capacitance Autowide AWC Series

- Electromagnetic Guidance NS-CPC Sensor

- AUTOWIDE™AWL

- Strip Guide Amplifier SGA3000

- PILOTJET

- Power Guide PG300, 500, 800

- Analog Position Transmitter FW22, FW31

- High-precision Position Transmitter GYKM-LT

-

Measuring Systems

-

Actuators

-

Movie

Inductive Autowide Sensors AWI Series

Overview

Introducing strip position detectors with outstanding environmental resistance that use an electromagnetic induction method!

AWI Autowide Sensors are used in CPC (Center Position Control) to continuously detect the position of the center of strip without physical contact.

These sensors are maintenance free and can be used continuously. There is no loss of sensitivity due to component deterioration over time. Not only will they perform steadily for a long period of time; they do not require on-going on-site calibration, which makes them significantly easier to use.

Note: Simple calibration using a calibration jig is required for initial adjustment on site.

Feature

- On-going on-site calibration is not necessary

- Maintenance free » Different to optical sensors, AWI sensors do not require maintenance

- Unaffected by light » These sensors are hardly affected at all by external light

- Even under extreme environments » These sensors are hardly affected at all by dust or scale

Operating principles

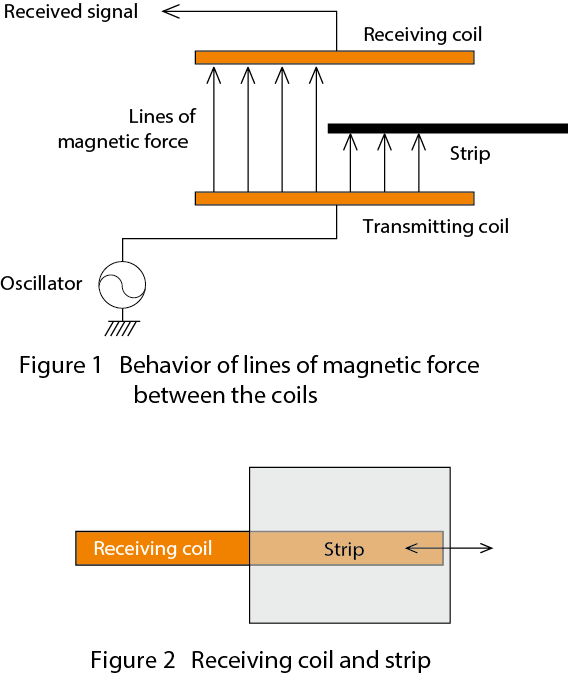

The AWI sensor generates lines of magnetic force between coils on either side of the strip and measures the changes in the position of the strip passing between the coils from the amount of change in these force lines (see Figure 1). The sensor has a transmitting coil and a receiving coil that are opposite each other, with the strip between them. The transmitting coil generates magnetic force lines and the receiving coil receives them. When a strip enters the gap between the transmitting and receiving coils, some of the magnetic force lines from the transmitting coil are blocked, which causes a variation in the magnetic force lines received by the receiving coil (see Figure 2).

Therefore, by calculating the amount of change in the lines of magnetic force received by the receiving coil, the position of the strip can be accurately detected.

Specifications

| Power supply | DC24 V (0.5 A, with an option uninstalled) |

|---|---|

| Deviation output | Digital output (CircLink output) Digital output (Ethernet/IP output) *Optional Analog output (± 200 mm / ±5 V) *Optional |

| Alarm output | “Healthy,” “No strip,” “Roll out,” “Excess deviation” |

| Ambient temperature during operation | 0 to 50°C |

| Ambient humidity during operation | 35 to 85% RH |

| Sensor accuracy | AWI***-3: ±3 mm AWI***-5: ±5 mm |

| Response time | 20ms |

Contact Us

Please use this form to submit your inquiries, feedback and/or requests to NIRECO.