PRODUCTS

-

Edge Position Control Systems(Sensors)

- Sensor / Electric Type Diagram

- Autowide Sensor AWE280A

- Photohead PH22VAS for vacuum environments

- High-temperature EPC sensor HE120A (for transparent webs)

- Ultrasonic Sensor UH05

- CMOS Linear Sensor SLH30

- Design Position Control DPC

- PHOTOHEAD PH16B / PH21

- PHOTOHEAD PH22

- Ultrasonic Autowide Sensor UHW051

- Ultrasonic Autowide Sensor UHW280

- Ultrasonic Autowide Sensor UHW500 / 700

- LINE FOLLOWER HEAD LH19

- LINE FOLLOWER HEAD LH110

- LINE FOLLOWER HEAD LH500

-

Edge Position Control Systems(Electric type)

- Sensor / Electric Type Diagram

- Guide roller mechanism (Electric type)

- AC servo actuator A353

- AC servo actuator A032

- AC servo actuator A152-□□□-20

- Motor-Driven Actuator K50 K50/A

- Liteguide Controller AE550/AE560

- Linear Actuator K300-200-20

- Compact Guide Roll Mechanism PGR series

- Compact Guide Roll Mechanism LCD series

- Guide Roll Mechanism

- Liteguide Controller AE1000

- Motor-Driven Actuator K12 series

- Motor-Driven Actuator K62 K62/A

- Motor-Driven Actuator K80

-

Edge Position Control Systems(Hydraulic type)

-

EPC related components

-

Tension Control Systems

- Tension Control System Diagram

- Intrinsically safe explosion-proof MB tension sensor

- MJ tension sensor (for vacuum environment) MJ**VAS

- MJ tension sensor (for vacuum environment) MJ**V

- Tension Controller TC920V

- Tension Controller TC680A/D

- Open loop Tension Control System TCD030T

- Tension Meter TM310T

- Tension Meter TM340

- MG Tension Sensor

- MJ Tension Sensor

- CJ Tension Sensor

- MB Tension Sensor

- Electro-Pneumatic Converter EN40

- Other related equipment

-

Automaic Register Control Systems

-

Print-to-cut Register Control Systems

-

Other Related Equipment

CJ Tension Sensor

Overview

Introducing a bearing-type tension sensor that can be cleaned with water.

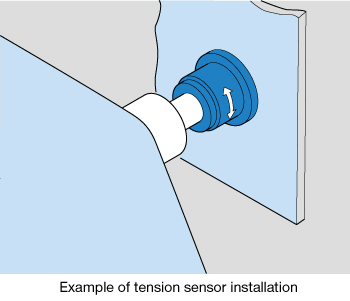

The CJ sensor is essential for tension control of sophisticated plastic films used in leading-edge industries, including flat-screen TVs, rechargeable batteries, thin and light solar cells, and organic EL lighting which is expected to become the next generation of lighting. The CJ series of tension sensors are bearing-type sensors, so they can easily be installed on existing lines.

Feature

- The CJ tension sensor has excellent dynamics, and its high spring-steel rigidity provides a high resonance point, making it ideal for high-speed lines.

- The load displacement of the MJ tension sensor is extremely low, making it effective for thin web lines (i.e., film, foil, etc.).

- The stainless version has an IP66-compliant protective housing that can handle being splashed with water when cleaning a production line.

- The use of a mono-block structure provides outstanding linearity and hysterisis.

- Because the bearing unit and sensor are integrated, the sensor has a low profile and requires minimal installation space, enabling it to easily be installed even in confined spaces.

Specifications

| Model | CJ200 | CJ500 | CJ1000 |

|---|---|---|---|

| Diagram number | MD0000360 | MD0000370 | MD0000380 |

| Diagram number with adapter unit | MD0000450 | MD0000460 | MD0000470 |

| Rated tension (N)*1 | 200 | 500 | 1000 |

| Maximum roll load (N)*1 | 200 | 500 | 1000 |

| Maximum overload*1,5 | 2000 | 5000 | 10000 |

| Roll displacement (μm·N) | 0.12 | 0.06 | 0.035 |

| Resonance frequency (Hz) *2 | 143.8 | 128.6 | 119.1 |

| Frequency response (Hz)*3 | 300 | ||

| Main unit mass (kg) | 1.0 (1.6) | ||

| Direction of resultant tension force | Forward or reverse | ||

| Mounting angle | Any desired angle | ||

| Supply voltage | ±15VDC ±1V (+15V/50mA,-15V/10mA) | ||

| Ambient temperature/humidity | 0 to +50°C, 35 to 85%RH (No condensation permitted) | ||

| IP Protection Rating | IP30 | ||

*1. The figures for rated tension, maximum roll load, and maximum overload are for double-sided detection.

*2. The resonance frequency figures are for the tension load during double-sided detection and at maximum roll load.

*3. The frequency response figure is with respect to a change of 1/10 in the rated tension.

*4. The figure in parenthesis is the mass including the adapter unit.

*5. The maximum overload represents the maximum value of the force exerted in the direction of the resultant force.

Download Tension Sensor Model Selection Software

Contact Us

Please use this form to submit your inquiries, feedback and/or requests to NIRECO.

Tokyo +81-42-660-7358

Osaka +81-6-6190-5550