-

Edge Position Control Systems(Sensors)

- Sensor / Electric Type Diagram

- Autowide Sensor AWE280A

- Photohead PH22VAS for vacuum environments

- High-temperature EPC sensor HE120A (for transparent webs)

- Ultrasonic Sensor UH05

- CMOS Linear Sensor SLH30

- Design Position Control DPC

- PHOTOHEAD PH16B / PH21

- PHOTOHEAD PH22

- Ultrasonic Autowide Sensor UHW051

- Ultrasonic Autowide Sensor UHW280

- Ultrasonic Autowide Sensor UHW500 / 700

- LINE FOLLOWER HEAD LH19

- LINE FOLLOWER HEAD LH110

- LINE FOLLOWER HEAD LH500

-

Edge Position Control Systems(Electric type)

- Sensor / Electric Type Diagram

- Guide roller mechanism (Electric type)

- AC servo actuator A353

- AC servo actuator A032

- AC servo actuator A152-□□□-20

- Motor-Driven Actuator K50 K50/A

- Liteguide Controller AE550/AE560

- Linear Actuator K300-200-20

- Compact Guide Roll Mechanism PGR series

- Compact Guide Roll Mechanism LCD series

- Guide Roll Mechanism

- Liteguide Controller AE1000

- Motor-Driven Actuator K12 series

- Motor-Driven Actuator K62 K62/A

- Motor-Driven Actuator K80

-

Edge Position Control Systems(Hydraulic type)

-

EPC related components

-

Tension Control Systems

- Tension Control System Diagram

- Intrinsically safe explosion-proof MB tension sensor

- MJ tension sensor (for vacuum environment) MJ**VAS

- MJ tension sensor (for vacuum environment) MJ**V

- Tension Controller TC920V

- Tension Controller TC680A/D

- Open loop Tension Control System TCD030T

- Tension Meter TM310T

- Tension Meter TM340

- MG Tension Sensor

- MJ Tension Sensor

- CJ Tension Sensor

- MB Tension Sensor

- Electro-Pneumatic Converter EN40

- Other related equipment

-

Automaic Register Control Systems

-

Print-to-cut Register Control Systems

-

Other Related Equipment

Guide Roll Mechanism

Overview

The Guide Roll Mechanism is used to correct meandering of the traveling web. The Guide Roll Mechanism is available with the center pivot system and the end pivot system.

NIRECO provides the guide roll mechanism suited to the requirements of web material quality, width, tension, correction quality and speed and installation conditions of a machine by applying its long experience of EPC technologies.

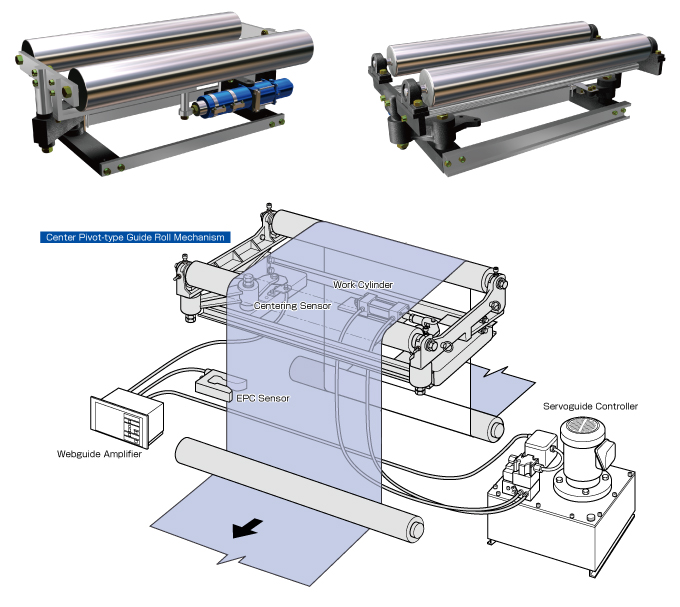

Center pivot system

The center pivot system allows the center of the extending surface of the web on the guide roller side to be the pivot center. Installation may sometimes be difficult, but in all other regards, this is the best intermediary guide roller system.

Features:

- Excellent stability and accuracy of control;

- No negative influence on the upstream side of the guide rollers;

- The design of the center pivot system means that adjustments can be made simply by applying torsion to the web, with minimal risk of creasing.

This makes the center pivot system ideal even for paper, metal and foil webs that have a high modulus of elasticity.

Specification:

| Model | Applications | Load | Roller material | Maximum tension N | Roller surface length mm |

|---|---|---|---|---|---|

| LCD-B | For business forms (has built-in width extender) |

Low | Aluminum | 250 | 550, 610 |

| LCD-01 | Offset rotary press | Intermediate | Aluminum | 1000 | 1000, 1100 |

| LCD-L | General use | Low | Aluminum or steel | 250 | 300~650 |

| LCD-M | General use | Intermediate | Aluminum or steel | 500 | 500~800 |

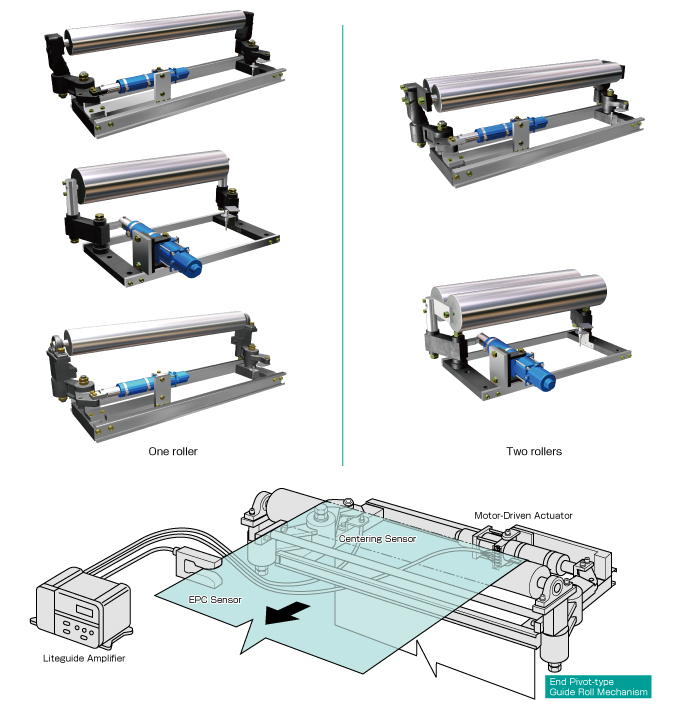

End pivot system

The end pivot system comes in two forms: the dual-roller S-wrap type and the single-roller 90°-wrap type. The dual-roller S-wrap end-pivot system is used in the middle of the web line, while the single-roller 90°-wrap end pivot system is installed at the point where the web makes a 90-degree change in direction.

Specification:

| Model | No. of roll | Wrap type | Load | Roller material | Maximum tension N | Roller surface length mm |

|---|---|---|---|---|---|---|

| LED-L1 | 2 | S-Wrap | Low | Aluminum or steel | 250 | 280~650 |

| LES-L1 | 1 | 90°-Wrap | Low | Aluminum or steel | 250 | 280~650 |

| LED-M | 2 | S-Wrap | Intermediate | Aluminum or steel | 1000 | 800~1600 |

| LES-M | 1 | 90°-Wrap | Intermediate | Aluminum or steel | 1000 | 800~1600 |

Contact Us

Please use this form to submit your inquiries, feedback and/or requests to NIRECO.