-

Edge Position Control Systems(Sensors)

- Sensor / Electric Type Diagram

- Autowide Sensor AWE280A

- Photohead PH22VAS for vacuum environments

- High-temperature EPC sensor HE120A (for transparent webs)

- Ultrasonic Sensor UH05

- CMOS Linear Sensor SLH30

- Design Position Control DPC

- PHOTOHEAD PH16B / PH21

- PHOTOHEAD PH22

- Ultrasonic Autowide Sensor UHW051

- Ultrasonic Autowide Sensor UHW280

- Ultrasonic Autowide Sensor UHW500 / 700

- LINE FOLLOWER HEAD LH19

- LINE FOLLOWER HEAD LH110

- LINE FOLLOWER HEAD LH500

-

Edge Position Control Systems(Electric type)

- Sensor / Electric Type Diagram

- Guide roller mechanism (Electric type)

- AC servo actuator A353

- AC servo actuator A032

- AC servo actuator A152-□□□-20

- Motor-Driven Actuator K50 K50/A

- Liteguide Controller AE550/AE560

- Linear Actuator K300-200-20

- Compact Guide Roll Mechanism PGR series

- Compact Guide Roll Mechanism LCD series

- Guide Roll Mechanism

- Liteguide Controller AE1000

- Motor-Driven Actuator K12 series

- Motor-Driven Actuator K62 K62/A

- Motor-Driven Actuator K80

-

Edge Position Control Systems(Hydraulic type)

-

EPC related components

-

Tension Control Systems

- Tension Control System Diagram

- Intrinsically safe explosion-proof MB tension sensor

- MJ tension sensor (for vacuum environment) MJ**VAS

- MJ tension sensor (for vacuum environment) MJ**V

- Tension Controller TC920V

- Tension Controller TC680A/D

- Open loop Tension Control System TCD030T

- Tension Meter TM310T

- Tension Meter TM340

- MG Tension Sensor

- MJ Tension Sensor

- CJ Tension Sensor

- MB Tension Sensor

- Electro-Pneumatic Converter EN40

- Other related equipment

-

Automaic Register Control Systems

-

Print-to-cut Register Control Systems

-

Other Related Equipment

Newspaper Rotary Press Automatic Register Control System CALGRAPH Smart N

Overview

A Sure Eye to Catch Any Misalignment

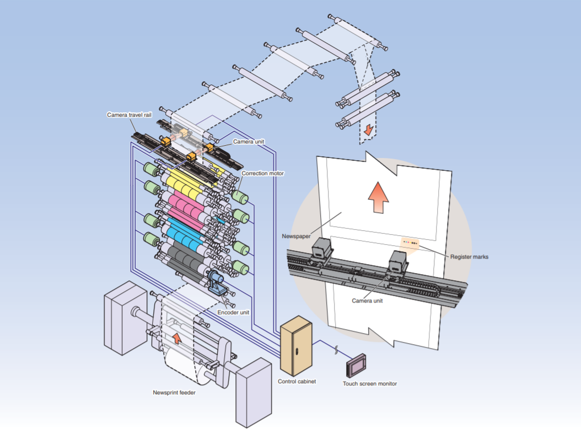

The CALGRAPH Smart N is a newspaper rotary press automatic register control system that utilizes image analysis technology. The system uses cameras with LED strobes to pick out the register marks, it analyzes what it sees, then adjusts the printing register up or down, left or right, with a high degree of precision. The CALGRAPH Smart N rapidly corrects any misalignment, minimizing registration time.

Feature

Automatic recognition of register marks

The system automatically recognizes register marks within images of the running web.

One controller per camera – as a standard feature

A simple arrangement of an independent controller for each printing direction, to enhance manageability.

Compact

The control panel unit is compact, with an LCD touch screen monitor. Since the control panel unit and the control cabinet are separate, you can select the locations to install them.

Accurate correction calculations based on tiny register marks

The CALGRAPH Smart N can perform registration using the register marks of the previous model (9000N). The system is largely unaffected by web fluttering. It makes accurate correction computations and performs rapid registration.

Optional functions

- Still images of the captured register marks can be viewed on a separate monitor.

- By connecting the system to a PC, web deviation data can be compiled and statistical data obtained during printing.

- Control of a customer’s system via the serial communication of correction signals is possible.

Components

System diagram

System components

Features an LCD touch screen panel.

Sends commands to each controller (for each printing direction) and displays information. Can be moved to a suitable location on the operations desk.

Each camera unit has an LED strobe and a CCD camera. The images captured by a camera are processed by a dedicated controller and used to detect registration marks.

This is the heart of the detection and control system, and houses the controllers. Since each controller operates independently, the system can simultaneously control all printing surfaces.

An encoder is installed where it rotates at a 1:1 relationship with the printing plate. An encoder unit and its printing cylinder must always be in phase together.

Contact Us

Please use this form to submit your inquiries, feedback and/or requests to NIRECO.