-

Edge Position Control Systems(Sensors)

- Sensor / Electric Type Diagram

- Autowide Sensor AWE280A

- Photohead PH22VAS for vacuum environments

- High-temperature EPC sensor HE120A (for transparent webs)

- Ultrasonic Sensor UH05

- CMOS Linear Sensor SLH30

- Design Position Control DPC

- PHOTOHEAD PH16B / PH21

- PHOTOHEAD PH22

- ULTRASONIC SENSOR UH01 series

- Ultrasonic Autowide Sensor UHW051

- Ultrasonic Autowide Sensor UHW280

- Ultrasonic Autowide Sensor UHW500 / 700

- PHOTOHEAD PH30 / PH31

- LINE FOLLOWER HEAD LH19

- LINE FOLLOWER HEAD LH110

- LINE FOLLOWER HEAD LH500

-

Edge Position Control Systems(Electric type)

- Sensor / Electric Type Diagram

- Guide roller mechanism (Electric type)

- AC servo actuator A353

- AC servo actuator A032

- AC servo actuator A152-□□□-20

- Motor-Driven Actuator K50 K50/A

- Liteguide Controller AE550/AE560

- Linear Actuator K300-200-20

- Compact Guide Roll Mechanism PGR series

- Compact Guide Roll Mechanism LCD series

- Guide Roll Mechanism

- Liteguide Controller AE1000

- Motor-Driven Actuator K12 series

- Motor-Driven Actuator K62 K62/A

- Motor-Driven Actuator K80

-

Edge Position Control Systems(Hydraulic type)

-

EPC related components

-

Tension Control Systems

- Tension Control System Diagram

- Intrinsically safe explosion-proof MB tension sensor

- MJ tension sensor (for vacuum environment) MJ**VAS

- MJ tension sensor (for vacuum environment) MJ**V

- Tension Controller TC920V

- Tension Controller TC680A/D

- Open loop Tension Control System TCD030T

- Open loop Tension Control System TCD050

- Tension Meter TM310T

- Tension Meter TM340

- MG Tension Sensor

- MJ Tension Sensor

- CJ Tension Sensor

- MB Tension Sensor

- Electro-Pneumatic Converter EN40

- Other related equipment

-

Automaic Register Control Systems

-

Print-to-cut Register Control Systems

-

Other Related Equipment

Guide roller mechanisms (Hydraulic type)

Overview

This guide roller mechanism corrects web meandering. There are two basic guide roller control methods: the center pivot method and the end pivot method.

Feature

Nireco has the optimal guide roller mechanism for the web material, width, tension, amount of web correction, speed, as well as the machine installation conditions. We offer these roller mechanisms to our customers.

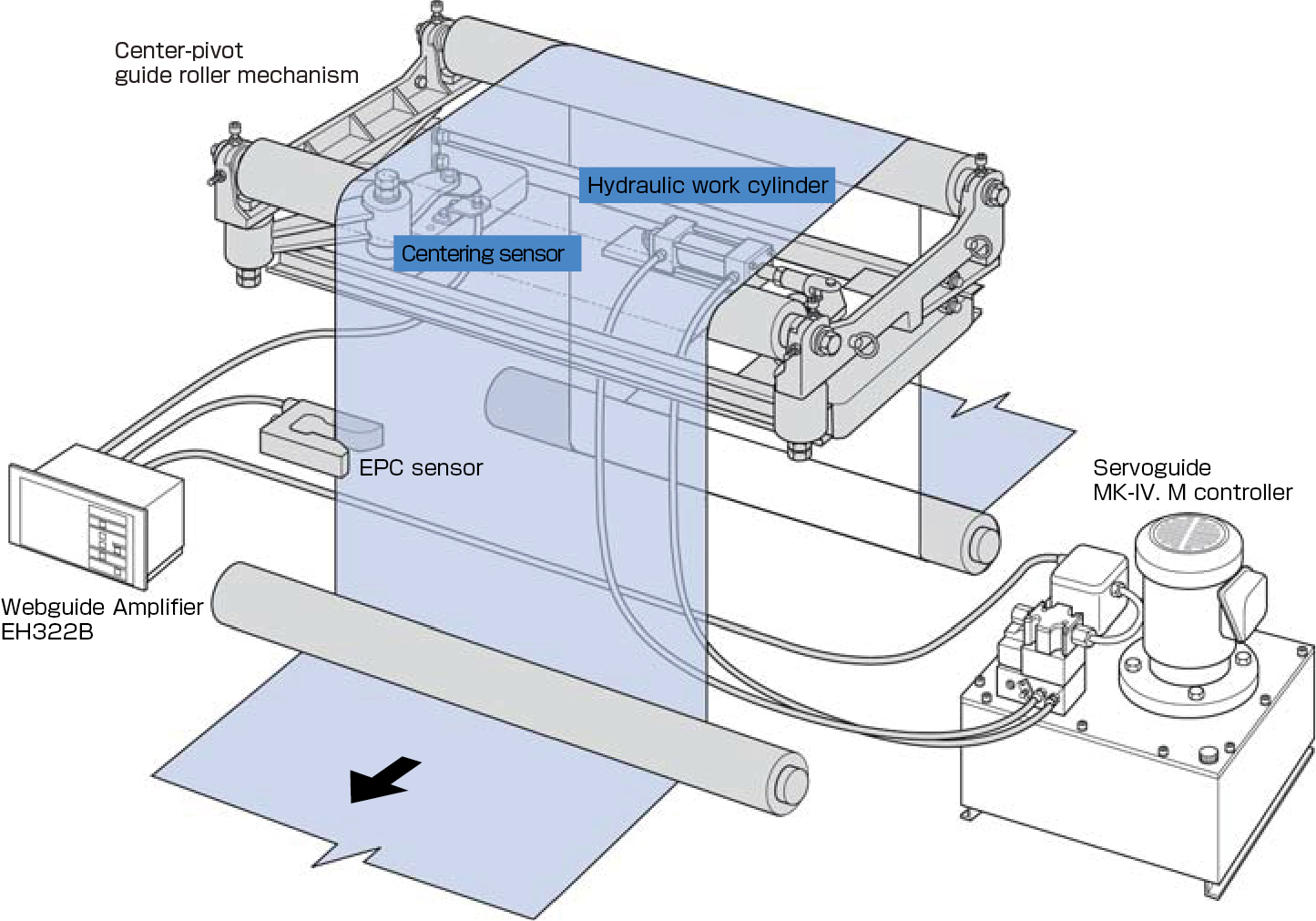

Center-pivot system(GCD)

The guide roller mechanism on a center pivot is designed so that the center of the web plane extension on the guide roller inlet side is the center of rotation. This guide roller system is used for web grades that can suffer permanent deformation or wrinkles when a difference in tension arises between both edges, i.e. non-expansion paper, newspaper, coated paper, metal, foil, cellulose, acetate, and brittle plastics.

Center-pivot system(GCD) diagram

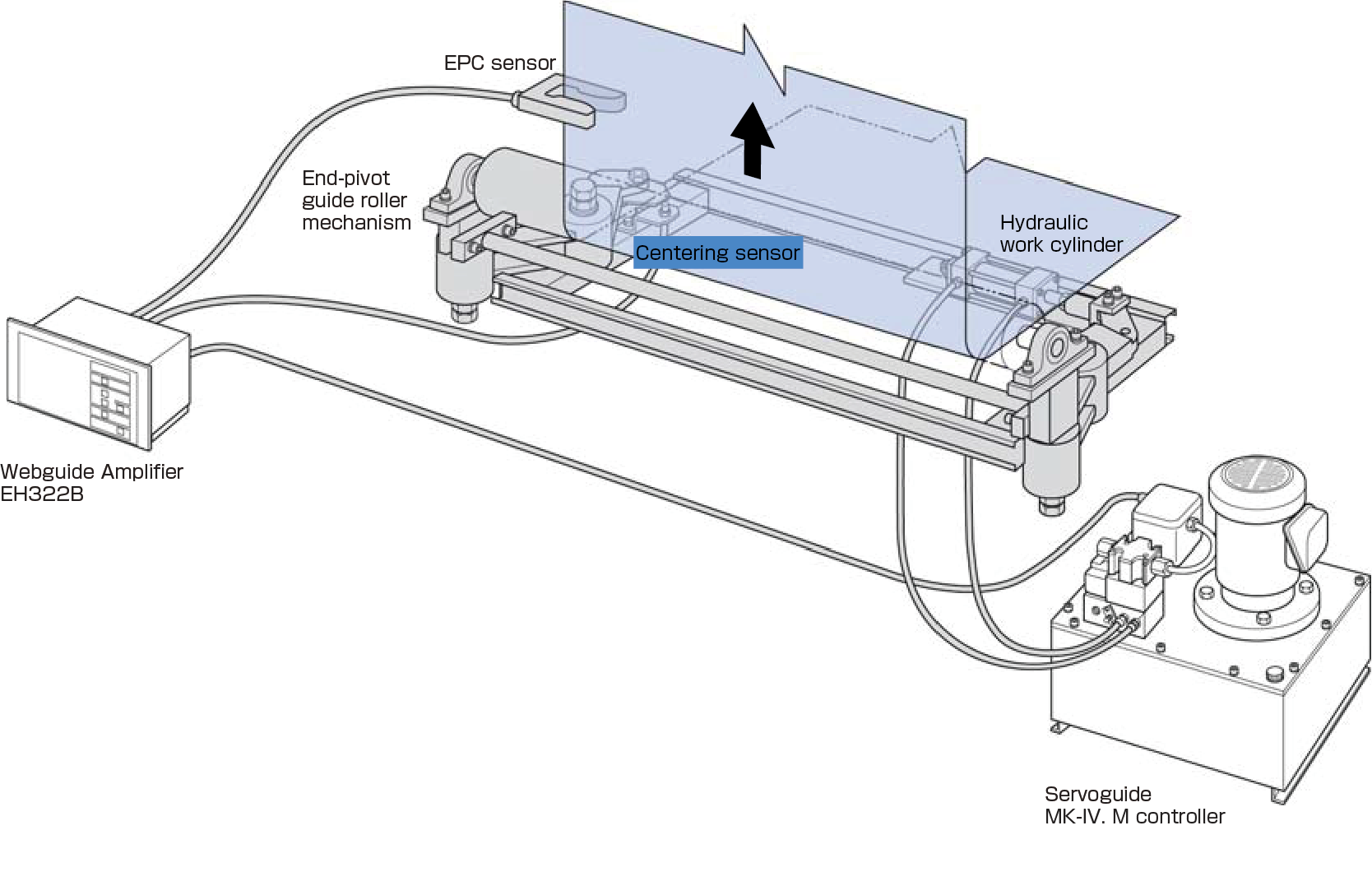

End-pivot system(GED)

The guide roll mechanism based in an end pivot is available with one, two or three rollers. The number of rollers is selected according to the place of use. This guide roller mechanism is used for webs that are expandable and easily absorb a difference in tension between both edges, i.e. cellophane, vinyl and polyethylene. It has the advantage of relatively easy installation in the middle of a line.

End-pivot system(GED) diagram

Contact Us

Please use this form to submit your inquiries, feedback and/or requests to NIRECO.