-

Edge Position Control Systems(Sensors)

- Sensor / Electric Type Diagram

- Autowide Sensor AWE280A

- Photohead PH22VAS for vacuum environments

- High-temperature EPC sensor HE120A (for transparent webs)

- Ultrasonic Sensor UH05

- CMOS Linear Sensor SLH30

- Design Position Control DPC

- PHOTOHEAD PH16B / PH21

- PHOTOHEAD PH22

- Ultrasonic Autowide Sensor UHW051

- Ultrasonic Autowide Sensor UHW280

- Ultrasonic Autowide Sensor UHW500 / 700

- LINE FOLLOWER HEAD LH19

- LINE FOLLOWER HEAD LH110

- LINE FOLLOWER HEAD LH500

-

Edge Position Control Systems(Electric type)

- Sensor / Electric Type Diagram

- Guide roller mechanism (Electric type)

- AC servo actuator A353

- AC servo actuator A032

- AC servo actuator A152-□□□-20

- Motor-Driven Actuator K50 K50/A

- Liteguide Controller AE550/AE560

- Linear Actuator K300-200-20

- Compact Guide Roll Mechanism PGR series

- Compact Guide Roll Mechanism LCD series

- Guide Roll Mechanism

- Liteguide Controller AE1000

- Motor-Driven Actuator K12 series

- Motor-Driven Actuator K62 K62/A

- Motor-Driven Actuator K80

-

Edge Position Control Systems(Hydraulic type)

-

EPC related components

-

Tension Control Systems

- Tension Control System Diagram

- Intrinsically safe explosion-proof MB tension sensor

- MJ tension sensor (for vacuum environment) MJ**VAS

- MJ tension sensor (for vacuum environment) MJ**V

- Tension Controller TC920V

- Tension Controller TC680A/D

- Open loop Tension Control System TCD030T

- Tension Meter TM310T

- Tension Meter TM340

- MG Tension Sensor

- MJ Tension Sensor

- CJ Tension Sensor

- MB Tension Sensor

- Electro-Pneumatic Converter EN40

- Other related equipment

-

Automaic Register Control Systems

-

Print-to-cut Register Control Systems

-

Other Related Equipment

Design Position Control DPC

Overview

At-roller-surface detection and off-roller detection

This system can be used in both at-roller-surface detection (that reduces the effects of play in the web on detection) and off-roller detection (that reduces the influence of the type of roller material on detection).

A wide range of light sources and filters

Combinations of the built-in LED lighting unit and the filters enable the system to cope with a range of roller surfaces including chrome-plated rollers and rubber rollers.

Feature

-

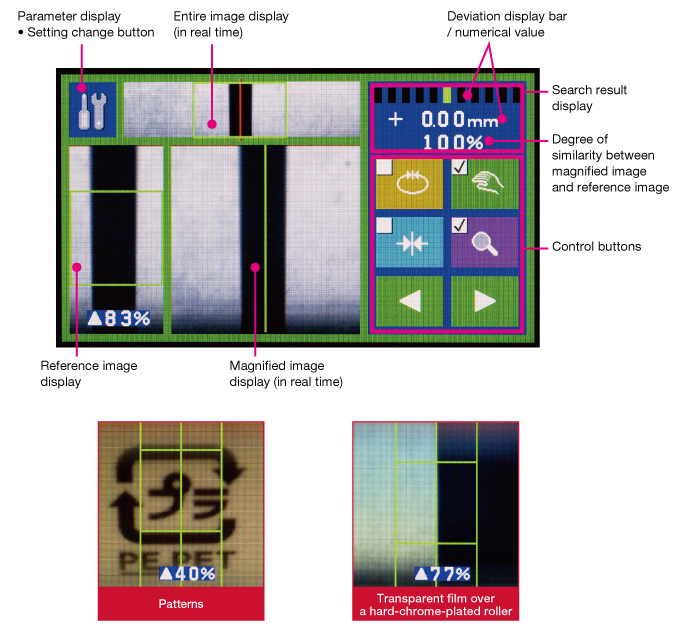

Pattern matching

The system takes reference positions from within the entire image (such as the line, edge, pattern and text) and stores them in memory, detects web meandering and sends out correction signals.

-

ZNCC (Zero-mean Normalized Cross-Correlation)

Stable detection is assured, even if there are variations in external light and print density. Easy search function

-

Easy search function

Simply specify the reference position from within the entire image and press the Search button to record the reference position in memory and start the detection.

Display and Operation

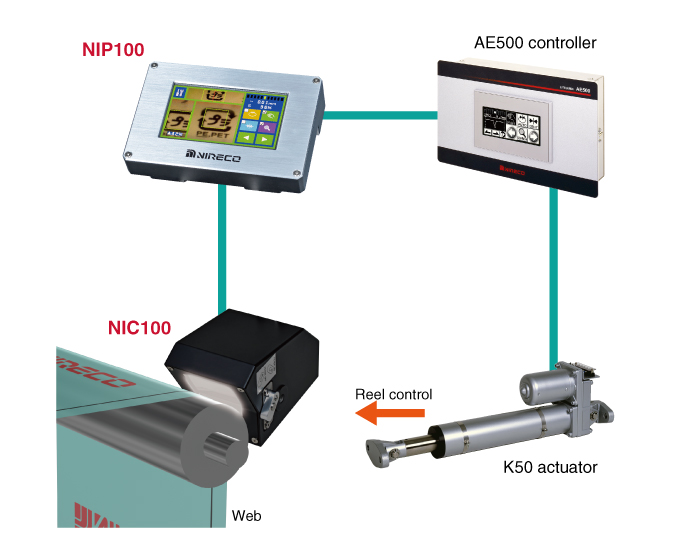

System components when under AE500 control

Specifications

| Model | NIP100 | NIC100 |

|---|---|---|

| External appearance |  |

|

| Power supply | DC24V(2A) | DC24V (1A) Supplied by the NIP100 |

| Ambient humidity | 0 to +50°C (No condensation) | |

| Light source | – | High brightness color LED (white) |

| Imaging element | – | CCD area sensor (VGA W640×H480) |

| Display function | Color touch-screen panel (4.3 inch) | – |

| Analog deviation signal output | DC 0 to +5V | – |

| Lock signal output | Open collector | – |

| Sensor roller diameter | – | φ 80mm or greater |

| Body material | ADC12 / A5052 | ADC12 / SPCC |

| Mass | Body 0.5kg | Body 0.7kg |

Contact Us

Please use this form to submit your inquiries, feedback and/or requests to NIRECO.