-

Edge Position Control Systems(Sensors)

- Sensor / Electric Type Diagram

- Autowide Sensor AWE280A

- Photohead PH22VAS for vacuum environments

- High-temperature EPC sensor HE120A (for transparent webs)

- Ultrasonic Sensor UH05

- CMOS Linear Sensor SLH30

- Design Position Control DPC

- PHOTOHEAD PH16B / PH21

- PHOTOHEAD PH22

- ULTRASONIC SENSOR UH01 series

- Ultrasonic Autowide Sensor UHW051

- Ultrasonic Autowide Sensor UHW280

- Ultrasonic Autowide Sensor UHW500 / 700

- PHOTOHEAD PH30 / PH31

- LINE FOLLOWER HEAD LH19

- LINE FOLLOWER HEAD LH110

- LINE FOLLOWER HEAD LH500

-

Edge Position Control Systems(Electric type)

- Sensor / Electric Type Diagram

- Guide roller mechanism (Electric type)

- AC servo actuator A353

- AC servo actuator A032

- AC servo actuator A152-□□□-20

- Motor-Driven Actuator K50 K50/A

- Liteguide Controller AE550/AE560

- Linear Actuator K300-200-20

- Compact Guide Roll Mechanism PGR series

- Compact Guide Roll Mechanism LCD series

- Guide Roll Mechanism

- Liteguide Controller AE1000

- Motor-Driven Actuator K12 series

- Motor-Driven Actuator K62 K62/A

- Motor-Driven Actuator K80

-

Edge Position Control Systems(Hydraulic type)

-

EPC related components

-

Tension Control Systems

- Tension Control System Diagram

- Intrinsically safe explosion-proof MB tension sensor

- MJ tension sensor (for vacuum environment) MJ**VAS

- MJ tension sensor (for vacuum environment) MJ**V

- Tension Controller TC920V

- Tension Controller TC680A/D

- Open loop Tension Control System TCD030T

- Open loop Tension Control System TCD050

- Tension Meter TM310T

- Tension Meter TM340

- MG Tension Sensor

- MJ Tension Sensor

- CJ Tension Sensor

- MB Tension Sensor

- Electro-Pneumatic Converter EN40

- Other related equipment

-

Automaic Register Control Systems

-

Print-to-cut Register Control Systems

-

Other Related Equipment

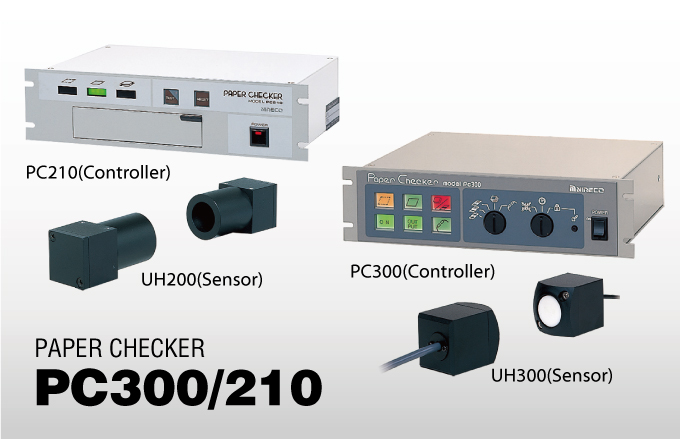

Paper Checker PC300/210

Overview

The Paper Checker series can be used as a double-sheet detector for sheet-fed presses, as well as a web splice or break detector. These products can be used for a wide range of materials including paper, aluminum laminate, poly-laminate, and plastic.

Main applications of the Paper Checker PC300

Detection of web splices or breaks

Rotary printing presses, slitters, laminators, coaters, windersPrevents 2-sheet overlap

Sheet-fed printing presses, laminators

Main applications of the Paper Checker PC210

Detection of web splices or breaks

Rotary printing presses, slitters, laminators, coaters, winders, etc.Prevents 2-sheet overlap

Box-making machines, laminators

Feature

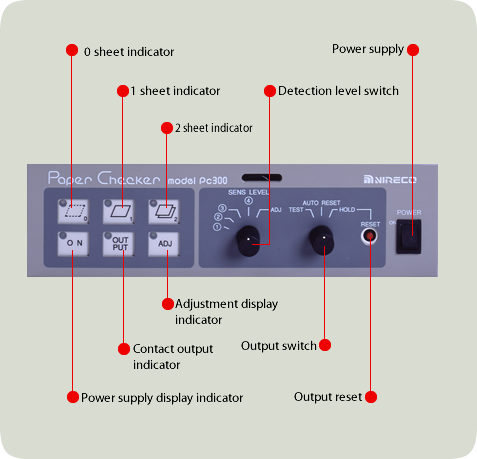

PC300

The Paper Checker PC300 and UH300 are a double-sheet feed detector developed specially for sheet-fed presses. Besides paper, it can also be used with aluminum laminate, poly-laminated paper, plastics and a number of other materials. It can also handle a wide range of thickness, and the thickness in use can be simply selected from a switch on the operation panel for easy changeovers. PC300 can detect double sheets of any material and prevents double sheets from being fed at once due to operator errors or omissions.

- Non-contact detection system

- No malfunction due to printed image or characters

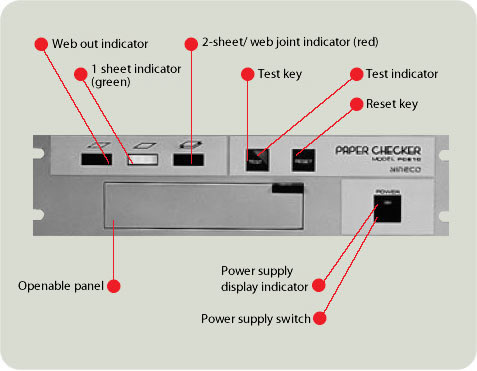

PC210

The Paper Checker PC210 and UH200 detect a splice or breakage of a web in every process of a web. In addition, it detects the feeding of double sheets by a sack machine which should feed one sheet at a time. When an abnormality is detected in each application, it is indicated on the controller and the output relay is activated. This contact causes the alarm buzzer to sound and the alarm indicator to light, thus notifying the operator or stopping the operation.

- Non-contact detection

- Broad applicable range of web (sheet) thickness

- All materials can be processed (paper, cellophane, aluminum foil, poly-laminate, etc.)

- No malfunctions are caused due to a pattern or character printed.

- Simultaneous detection of web splice and breakage

- Color and material of a splice tape and splicing* have no effect on detection.

(butt joint and overlap joint on splice detection)

Specifications

PC300(Controller), UH300(Sensor)

| Detecting method | Non-contact detecting system |

|---|---|

| Application | Double-sheet detector for sheet-fed press |

| Material type | Paper, aluminum laminate, poly-laminate, plastics Material thickness: 0.04 to 1.0mm |

| Input | Synchronous signal, output reset signal |

| Operating speed | 15000sph (max) |

| Power supply | 100 to 240V AC, 50/60Hz |

| Power consumption | 10VA (max) |

| Mess | Controller 2kg, Sensor 0.4kg (one pair, including cables) |

| Ambient temp. | 0 to 50℃ |

PC210(Controller), UH200(Sensor)

Web splice detection

| Web thickness | 1μm to 0.8mm |

|---|---|

| Splice width | 20mm or more |

| Line speed | 1000m/min or less |

| Inter-lock input | a-contact, rating: 5V DC, 10mA |

Web break detection

| Web thickness | 50μm to 0.8mm |

|---|---|

| Line speed | 1000m/min or less |

Double-sheet feed detection

| Sheet thickness | 15μm~0.8mm |

|---|

Common specifications

| Power supply | 100 to 240V AC, 50/60Hz |

|---|---|

| Power consumption | 10VA |

| Contact output | C-contact Rating : 240V AC, 0.1 A 24V DC, 0.1 A |

| Weight | Controller: 2kg Sensor: 0.5kg (one pair) |

| Cable length | 5 meter each |

| Ambient temperature | 0 to +50℃ |

Contact Us

Please use this form to submit your inquiries, feedback and/or requests to NIRECO.